How To Design A Product

All products start with just an idea. These ideas often grow and evolve to look very different from when we first imagined them, but they all start from the same humble beginnings. If you have an idea for your own product, this post is for you. We’ve laid out the fundamental principles you’ll need to start designing your product.

Firstly, design with manufacturing in mind

DFM (Designing for manufacturing) essentially means that you consider the manufacturing process before you begin designing your product. Your specifications for the product need to align with the capabilities of the manufacturer. Before you begin designing, you’ll need to understand how this product will be made and what materials will be used. This is why a collaborative approach works best.

Consider your products volume - it shouldn’t be heavier than 170g

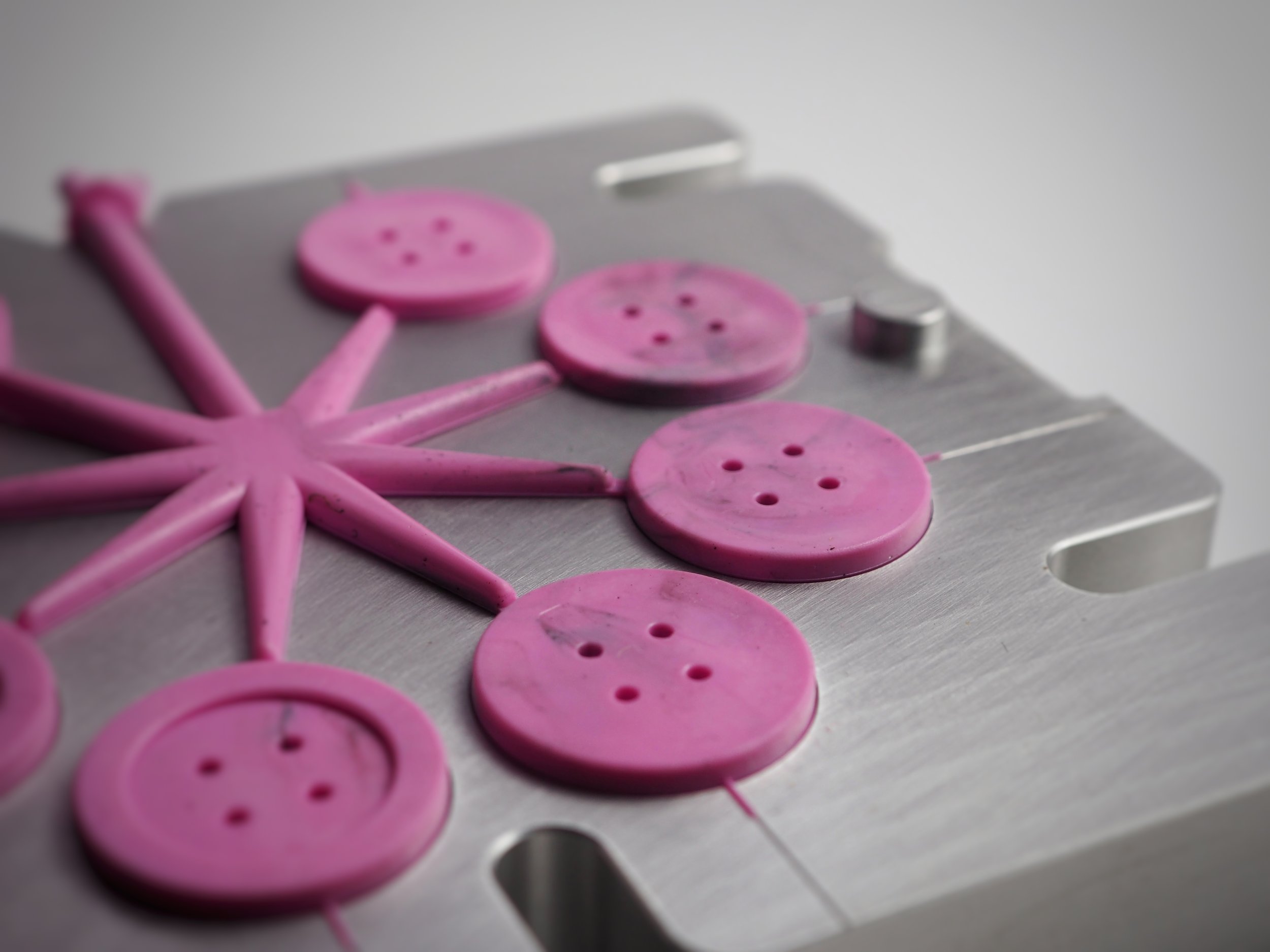

Normal injection molding usually limits you to very small components like pen lids, which can only weigh a few grams. This is how most injection molding is done and this method is mainly used in China for mass produced goods. However, our machines at Sustainable Design Studio are able to go up to 170g (which is much higher than average). This weight allowance allows you to create an array of products including, jewellery, cups, coasters, combs and lots more.

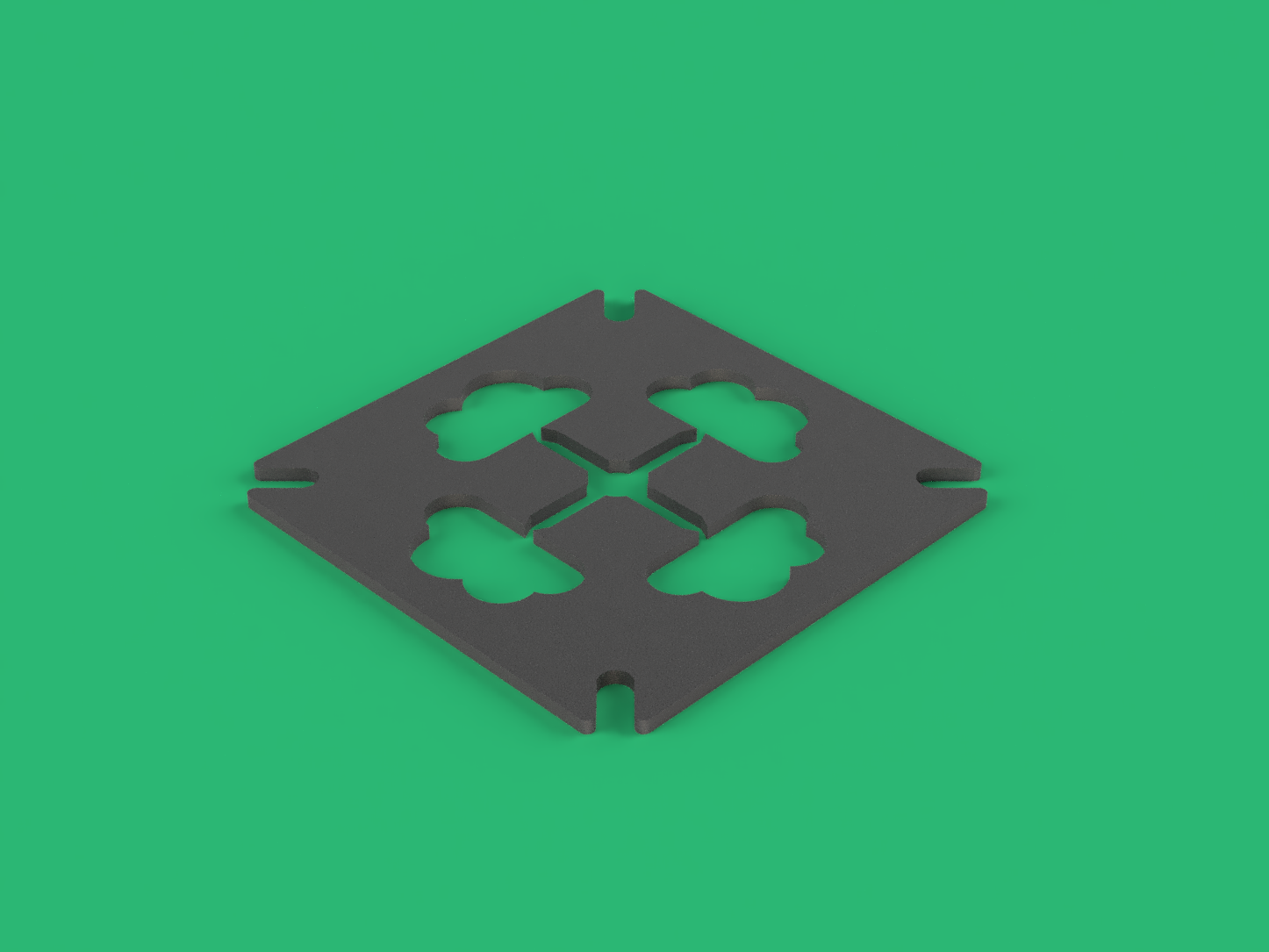

Mold shape is important - a mold cavity defines the shape of the part

Injection molding is similar to building a sandcastle. Your bucket is your mold and the sand is the plastic. In order for the sandcastle to take shape, you must be able to lift the bucket off, then you’re left with the sandcastle shape on the exterior of the product. If you want to create something hollow, you would need to create two halves and join the halves together after the injection process. Similar to how easter eggs are made.

Curves and angles are your friends

Plastic shrinks. When you heat plastic and it cools down afterwards, it shrinks in the process. When it shrinks it shrinks around things. This is why it’s important to put angles on the male parts of the molds. However, this process will also impact the shape of your product, making it more curved with more angles, as opposed to square shaped. This is why plastic plant pots are tapered.

Make your product unique, in a simple way

Almost every consumer good is competing in a saturated market, meaning that having a unique element to your creation has never been more important. A simple way to add some oomph to your product is to integrate another product or feature to make it even more attractive. For example, a coaster is great but a coaster that can charge your phone is even better. It’s very simple to add the electronics to a coaster to turn it into a wireless charging pad, and it only costs about £1 to add. A small extra charge to your production costs would allow you to quadruple the price of your product.

Think about the waste you want to work with

Design your product for the waste you want to deal with, not the other way around because some products just don't work with some plastic types. For example, polystyrene allows your product to look like it's made of granite stone. It can look shiny and polished but it doesn’t allow for fine details, and doesn’t work for very small objects like buttons or beads.

If you want to create small detailed objects that have lots of little details like fine writing or cool logos then polypropylene is a better option. It’s fluid and will always give you the details if you want. If you're not really fussed and you just want really colourful patterns with a large range of colours, then HDPE is a good choice.

When you design a product, also bear in mind that there’s a plethora of colours to choose from. One of the major advantages to using our equipment, unlike many others, is that you get this beautiful polymarble texture that gives you this amazing unique colour, allowing you to emphasise that your products are made from recycled plastic.

Looking for help designing your sustainable product?

We’ve worked with many different businesses, charities and people to help turn their weird and wonderful ideas into realities, and have learned so much along the way. We help take the drive and passion from entrepreneurs and give them the tools, knowledge and know-how to get started manufacturing their products. If you have an idea and would like some help and advice to get started, we’d love to hear from you.

What’s possible with Sustainable Design Studio?

Take a look at some of our client success stories.