Concepts & Ideas: Relief Recycle Station

We understand this can be a sensitive topic. This concept is developed by our director, who spent 5 years in disaster response before starting Sustainable Design Studio. All images are AI-generated.

The Concept

In the immediate aftermath of natural disasters, conflicts, or humanitarian emergencies, essential items like bottled water, food containers, and plastic tarpaulins are rapidly distributed. These lifesaving materials are critical—but they also generate a wave of plastic waste in places where infrastructure has collapsed and waste systems no longer function.

At the same time, communities urgently need tools to rebuild. Shelter pegs, fixings, fasteners, utility items. These basic components are often difficult and expensive to import.

The Relief Recycle Station is a self-contained, shipping container-based microfactory designed to solve both challenges at once. It uses compact, field-ready injection molding equipment to turn collected plastic waste—such as bottle caps and tarp offcuts—into useful products that aid recovery. Operated by local staff and supported by NGOs, it closes the loop between aid and action, waste and rebuilding.

Why It Matters?

Disaster zones are chaotic. Infrastructure is damaged or destroyed. Waste piles up. Plastic is often burned, buried, or abandoned—creating serious environmental and health risks.

At the same time, the need for basic components skyrockets: tent pegs for shelters, cable ties for repairs, clips for tarpaulin structures, hygiene tools, and more. But these items are typically shipped in, causing delays and logistical challenges.

Relief Recycle Station offers a practical, circular solution:

It transforms local plastic waste into urgently needed tools.

It reduces the environmental burden of plastic waste in crisis zones.

It creates jobs and training for displaced people or those without access to formal work.

It empowers communities to contribute to their own recovery, using technology that’s simple, scalable, and human-centred.

How It Could Work?

Tourists get a souvenir with a story, and a sense of participation in the circular economy. For a startup or nonprofit, it’s a way to generate income, raise awareness, and showcase sustainable micro-manufacturing.

1. Deployment

A shipping container equipped with Sustainable Design Studios micro recycling tools is deployed into a disaster-affected area. It includes a shredder, injection machine, tools, molds, and training materials.

2. Collection

Local community members are paid or incentivised to collect waste plastics—water bottle caps, food containers, tarps, etc.—and bring them to the Station.

3. Processing

Processing

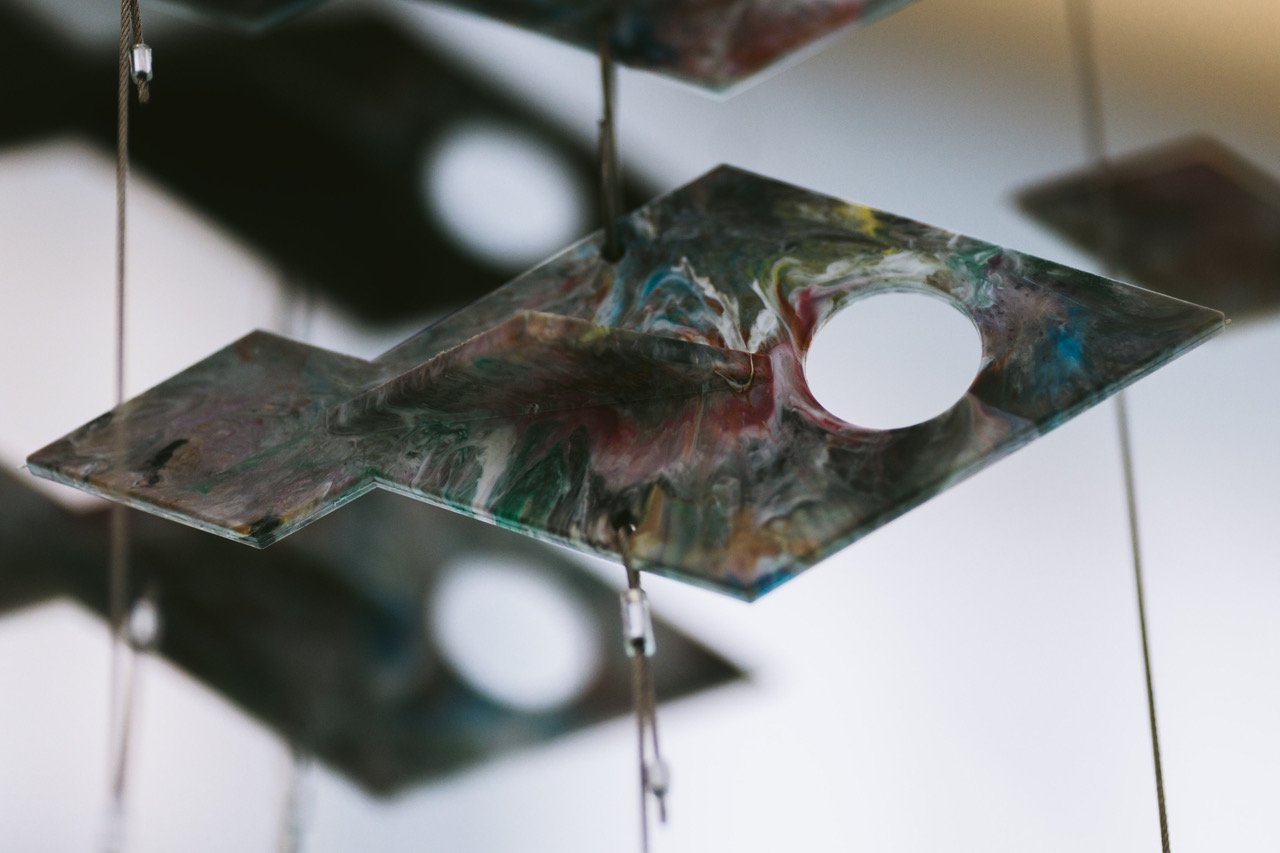

The waste is shredded, melted, and injection-moulded into useful items such as: Tarp Clips, Cable Ties, Tent Pegs.

4. Distribution

The finished products are distributed by NGOs, made available at local coordination hubs, or used directly in rebuilding efforts (e.g. schools, health centres, temporary shelters).

5. Training & Upskilling

Displaced individuals or unemployed locals are trained in operating the machines, quality control, and small-scale production—giving them skills they can continue to use even after the crisis

6. Establishing a Long-Term Hub

Once the immediate recovery phase is complete, the Relief Recycle Station can transition into a permanent or semi-permanent community recycling hub. With trained local staff, existing tools, and a proven system, the Station can continue processing plastic waste from the area.

Required Sustainable Design Studio Items

-

Desktop Shredder

-

Injection Mini

-

Fume Extractor

-

Custom Moulds

-

Consultancy & Support

Estimated Budget: £20,000/€24,000/$27,000

Wider Applications

While designed for disaster response, the Relief Recycle Station concept can be adapted to:

Refugee and displacement camps

Post-conflict zones and rebuilding regions

Remote island communities with high import costs

Education and resilience training programs

It could even form part of long-term development strategies, helping regions prone to flooding, conflict, or extreme weather build their own capacity to turn waste into resilience.

This same model could support programs run by:

NGOs and aid agencies

Social enterprises in affected regions

Donor-backed circular economy pilots

As mold designs evolve, so can the product offerings—tailoring production to the unique needs of each crisis or community.

Why It’s A Great Idea?

Closes the loop between aid inputs and recovery tools

Reduces reliance on imports by producing items locally

Minimises plastic pollution in disaster-affected areas

Creates livelihoods in areas with high unemployment

Mobile, modular, and scalable—fits inside one shipping container

Uses proven, accessible technology from Sustainable Design Studio and similar toolkits

Interested in Starting Something Like This?

This concept is ready to be brought to life. Enquire now to explore how you could pilot or adapt this idea for your own location or community.

Related Resources.

Case Studies